What can using this technology mean for you? Would these results make a difference?

Moving to a process managed by a SFDC system will eliminate the need for a paper-based system, enable single entry of data, reduce administrative load on production management and improve quality control

TotalControlPro is recovering about 30mins per day per shop floor operator in lost production time, and saving me a day a week in managing job data.

TotalControlPro has the ability to answer all of these with real-time feedback of valuable data” “… and allowed us to ensure accurate costings and remain competitive in an increasingly lean-priced market.

We had the system up and running within the week, we saw a 10% decrease in downtime and a 15% increase in productivity.

See how TotalControlPro can benefit you

Select your job role to see how TotalControlPro can transform your day-to-day operations and understanding.

Use TotalControlPro across any industry

A&M EDM

A&M EDM produce a wide range of precision manufacturing materials making paper-based tracking systems unreliable and data, inaccessible. They needed a way to accurately identify the return on their investments and an integrated system that could be carried out across their entire manufacturing plant, putting them back in control of their facility.

Silverstone Composites

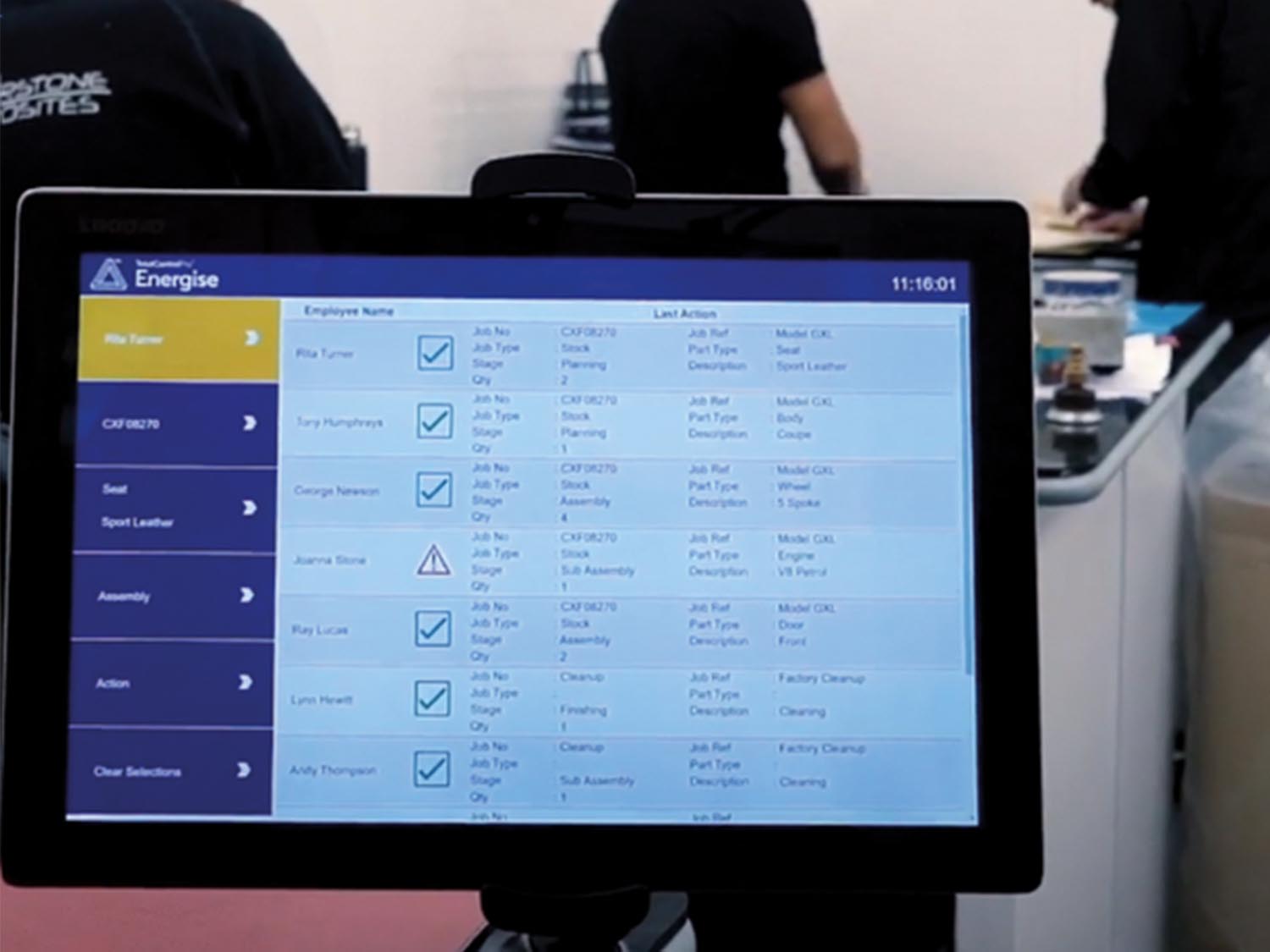

With their current systems Silverstone Composites weren’t able to pin point the stoppages in production due to miscommunication, delays in manufacturing and lack of stock availability. TotalControlPro quickly noticed this was an issue. We highlighted to their team that being able to visualise these issues would enable all team members to view real time red flags around current orders and react to each situation accordingly.

Kal Tire

The business wanted to update its system and bring modern technology to their production process. They were looking to produce reports and follow big data rather than make decisions based on spreadsheets and paper-based systems. At the heart of Kal Tire’s manufacturing business is the belief that what gets measured gets done making performance data vital to their daily operations and key to reducing costs and continually improving efficiency and quality.

Siemens

Siemens needed a system to help them monitor the effectiveness of employees and asses the productivity of different team configurations. TotalControlPro provided an easy-to-implement solution that could be put into place quickly, and efficiently allowing them to identify employee combinations that lead to increased productivity.

The Albion Knitting Company

As a knitwear company, The Albion Knitting Company is an example of a manufacturing organisation that is heavily labour intensive. With a multinational & multilingual workforce, carrying out repetitive tasks, they needed a simple & effective track and trace reporting system and a platform to clearly communicate work instructions.

See how TotalControlPro can power your smart factory

Build your smart factory around your business. Choose between one or all seven modules to start your digital transformation, prioritising your needs and pain points. With no need to change your processes or hardware, TotalControlPro is the flexible solution that enables you to take control of your manufacturing.

Getting Started

Whether to solve a specific challenge in one area of your operations, or to enable synchronised manufacturing across your plant, the Manufacturing Operations Platform can be onboarded quickly and effectively.

- Per user pricing

- Modular onboarding,

- Training and Support: 3 levels of support to suit budget and inhouse digital readiness or skills.

Resource Management

All TotalControlPro systems start with our resource management module, where you can manage all aspects of your people, plant and production. Resource Management comes to life when paired with any of our six dynamic modules.

Inventory

Never run out of materials or components again with automated ordering and instant stock notifications using our Inventory module. Know your stock status at the touch of a button and log arrivals and despatches for complete end-to-end visibility of the manufacturing process.

Manufacturing Execution System

Connect, analyse, adapt and evolve your manufacturing using our enterprise-ready MES system. Plan, receive and produce orders that are timed, tracked and traced from order to delivery, enabling you to make smart, data-driven decisions.

Planning & Scheduling

Set priorities, manage capacity and schedule part-types/ work items dynamically, giving you control over the entire manufacturing process.

Shop-Floor Interface

Capture live data from the shop floor using simple plug-and-play hardware, helping you to know what’s in production, at what stage, and when its due for completion. Digitise the entire production process by sending orders to work stations and adapting production schedules from anywhere in the world.

Customer Management System

Transform your customer relations with our management system that integrates CRM functionality directly with production. Take custom order designs and specifications and send them directly to the factory floor. Track from customer order through the manufacturing process to delivery, all at the click of a button.

Manufacturing Intelligence

Analyse, adapt and evolve with intelligence tailored to you and your needs. Use off-the-shelf reports or built your own to understand people, product and process data that can tell you how many orders are delivered on time, first time at the correct cost.

Business Integration

Complete your smart factory set-up by integrating TotalControlPro with multiple software sources – from accounts to ERP – to gain enterprise-level analysis of your manufacturing business. Work with our integrations team see how your data can feed in to TotalControlPro to give you a rich business overview.