Traditional MRP vs Cloud MRP

With so many acronyms popping up within the world of Industry 4.0, it can be difficult for manufacturers to keep up. Instead of trying to work out if you need Machine Resource Planning (MRP), Enterprise Resources Planning (ERP), or Manufacturing Operations Management (MOM); you should be considering whether your business needs a more traditional on-premises system or a flexible cloud system.

In the article below we briefly outline the differences between Traditional MRP vs Cloud MRP

Traditional MRP

Traditional manufacturing resource planning (MRP) software has been around since the 1960s. Cloud manufacturing resource planning (MRP) is the new kid on the block – it’s easier to use and more affordable than traditional MRP software, so you can make your operations faster and more efficient.

After the introduction of MRP in the 1960s, it became the norm for manufacturing, but customer needs and production planning have changed drastically ever since. Forecasting is a key component of traditional planning methods such as MRP. Using forecasting to improve sales and operations planning (S&OP) presents an uphill struggle– you might get there, but not quickly or at all. The traditional approach to forecasting is to combine data from multiple sources – usually spreadsheets – with variables, like historic sales data and predicted batch sizes.

Cloud MRP

With Cloud MRP software, all data and the software itself are stored on a server and can be accessed from any device or location over the internet. Users do not have to worry about installing or updating software with cloud MRP software. Furthermore, the end-user does not need to access the source code of the software or worry about server infrastructure or any aspects related to the back end of the MRP software.

Some giant corporations built their businesses around on-premise software, but cannot ignore the increasing popularity and effectiveness of Cloud MRP solutions. This, in turn, results in legacy systems slowly but steadily moving into the cloud.

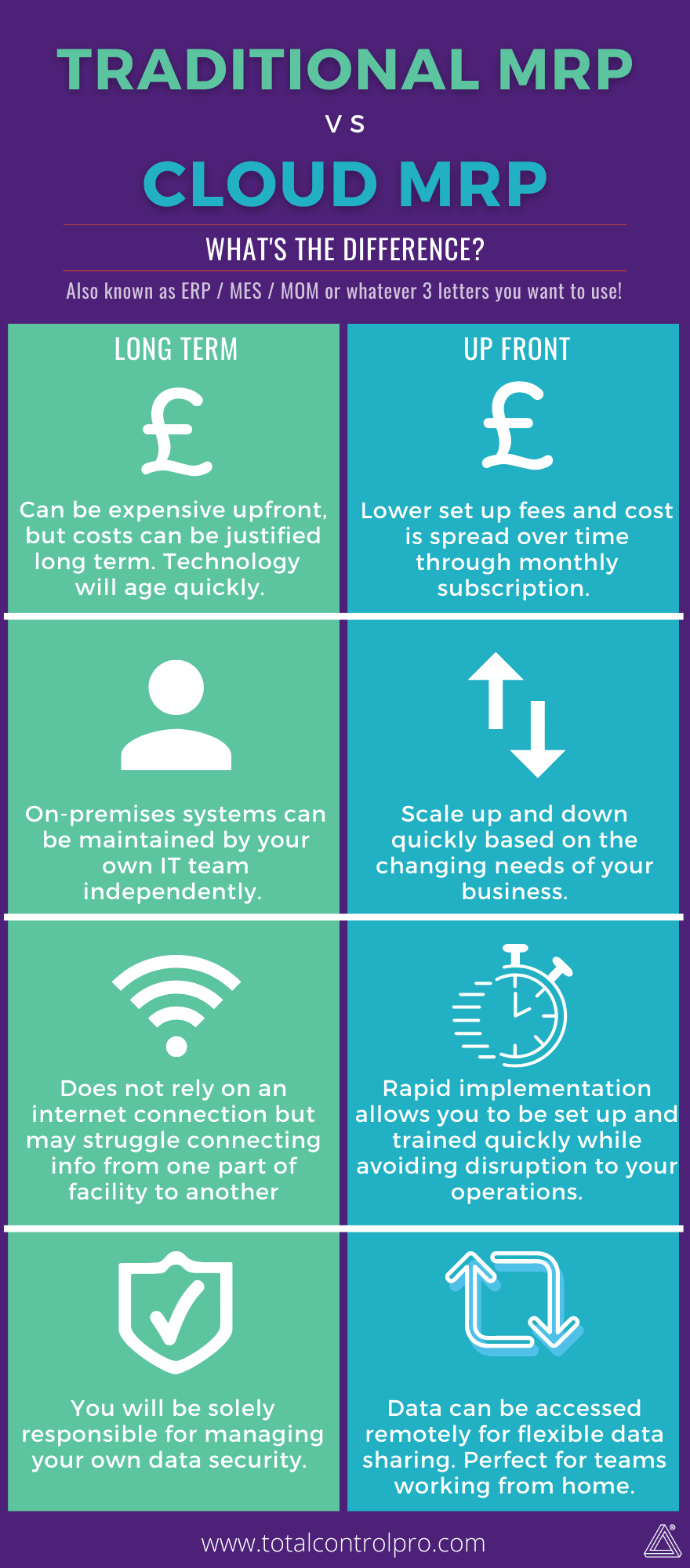

Compare the two in the infographic below:

Research indicates that after a year of tracking data, business intelligence systems are often abandoned by managers who find them too time-consuming to use effectively. Cloud-based enterprise resource planning (ERP) systems offer an alternative that is easier to deploy and use, and they make it possible for companies to access real-time data. They also help companies transform their traditional MRP into a more intelligent and efficient Cloud MRP system so they stay competitive in the marketplace.

Conclusion

In short, TotalControlPro® helps manufacturers manage operations effectively.

TotalControlPro® brings a real-time, cloud-based AI technology delivered via an agile Smart Manufacturing platform. This user subscription-based model delivers smart work planning, execution, process control, inventory management and real-time performance reporting. The right resources, at the right place, at the right time, doing the right task, against the right job.

In addition, we do not charge upfront set-up costs but invest our services into a long-term monthly SAAS agreement so you can focus on your business and maximise your ROI.

If you would like to see how to take Total Control of your manufacturing operations, contact us.